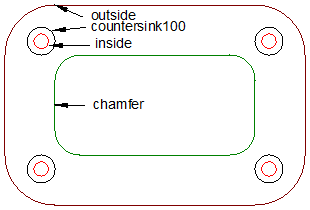

Description

chamfering is the same as beveling an edge. An example would be the panel cutout around an engine gauge. This is done with a chamfer mill after the cutout is cut. This chamfer mill is 1/4″ diameter, 90 degree included angle.

Note that the surface to be chamfered will need to have a level surface.

On all Panel Pro’s level can be verified with a dial indicator and manual shimming

If you have a Panel Pro 5925 or 6126, you can use the Measure Pro to do a Z calibration to compensate for normal out of level conditions.

Note the countersinks in the gallery pictures were done using a flat 1/8″ end mill and the AvCAM countersink method. The chamfer was done using the chamfer mill.