Description

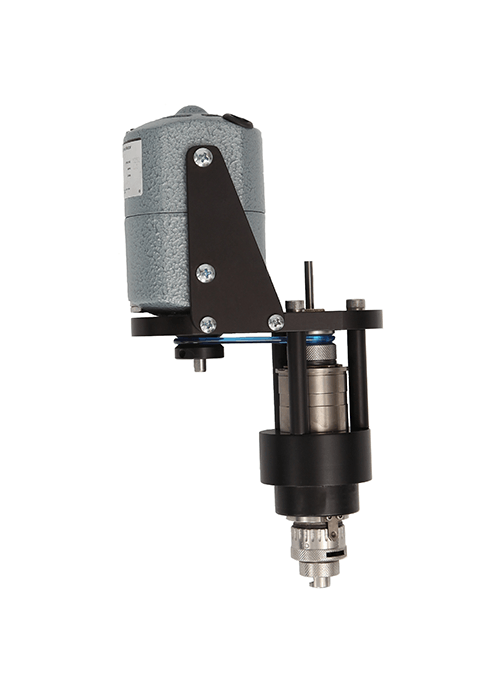

EG2 Engraver

The EG2 engraving accessory expands the capabilities of any model of the Panel Pro. It has the precision to engrave through a top layer of paint revealing a colored sub layer. With this

accessory, you can engrave placards, circuit breaker panels or directly on the surface of an instrument panel.

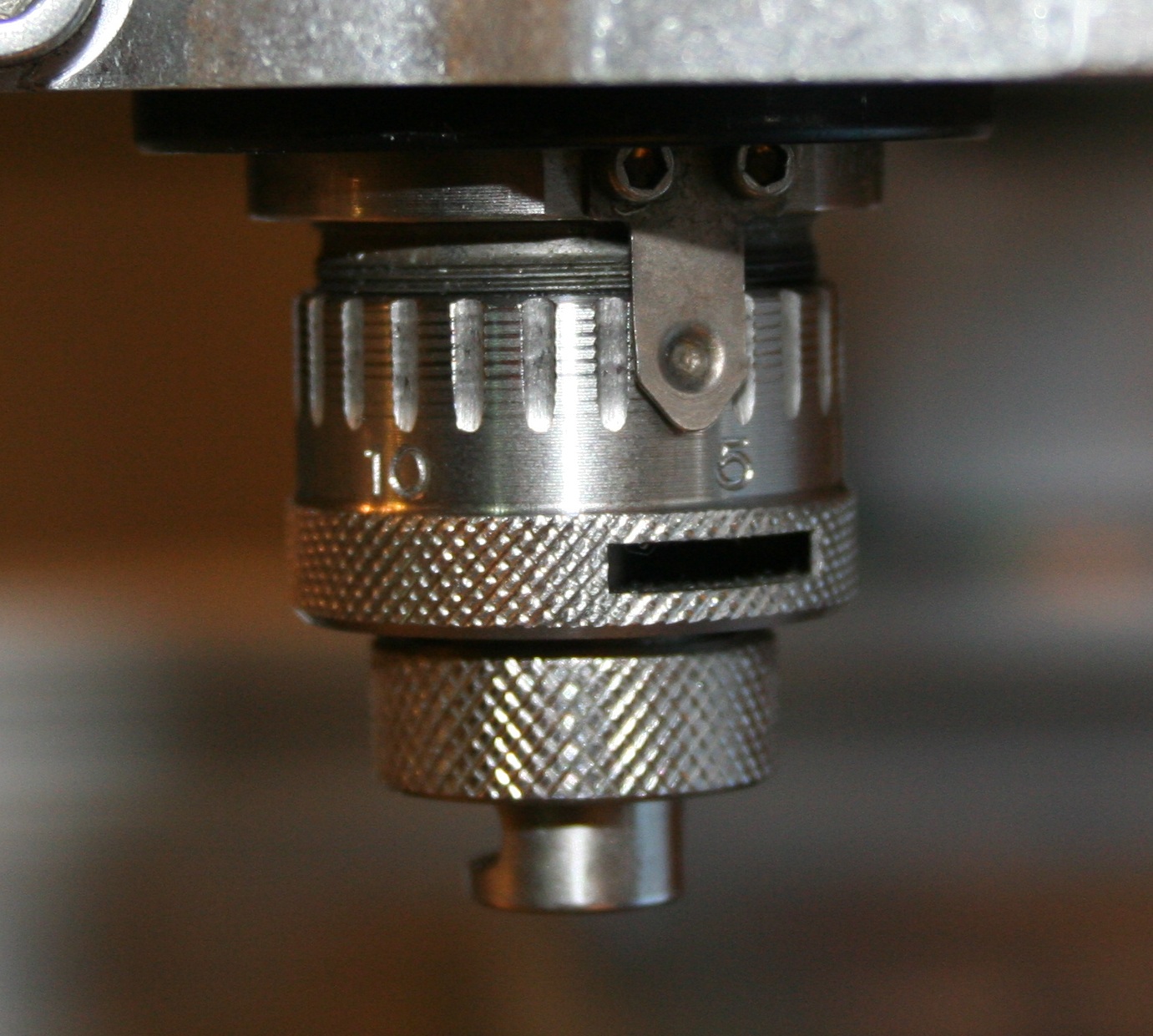

The EG2 engraver starts with a precision spindle assembly that features a nose that is adjustable in .001 increments. It has a replaceable nose. It is mated to a heavy duty ball bearing motor in an adapter that mounts the assembly in the Panel Pro 4824, 5624, or 5925 CNC panel cutters.

The cutter is a top load 11/64 by 6 1/2 engraving cutter. The spindle and cutter combination assures precise rotation so that very fine .005 tip width cutters approach the material with the cutting edge rather than the back side of the cutter. The top load design means the cutter can be changed without disturbing the EG2 mounted in the Panel Pro accessory mount.

The micrometer adjustment assures precise .001 inch adjustments, or even between detents for sub one thousands adjustments.

The EG2 can repeat precision depths time after time.

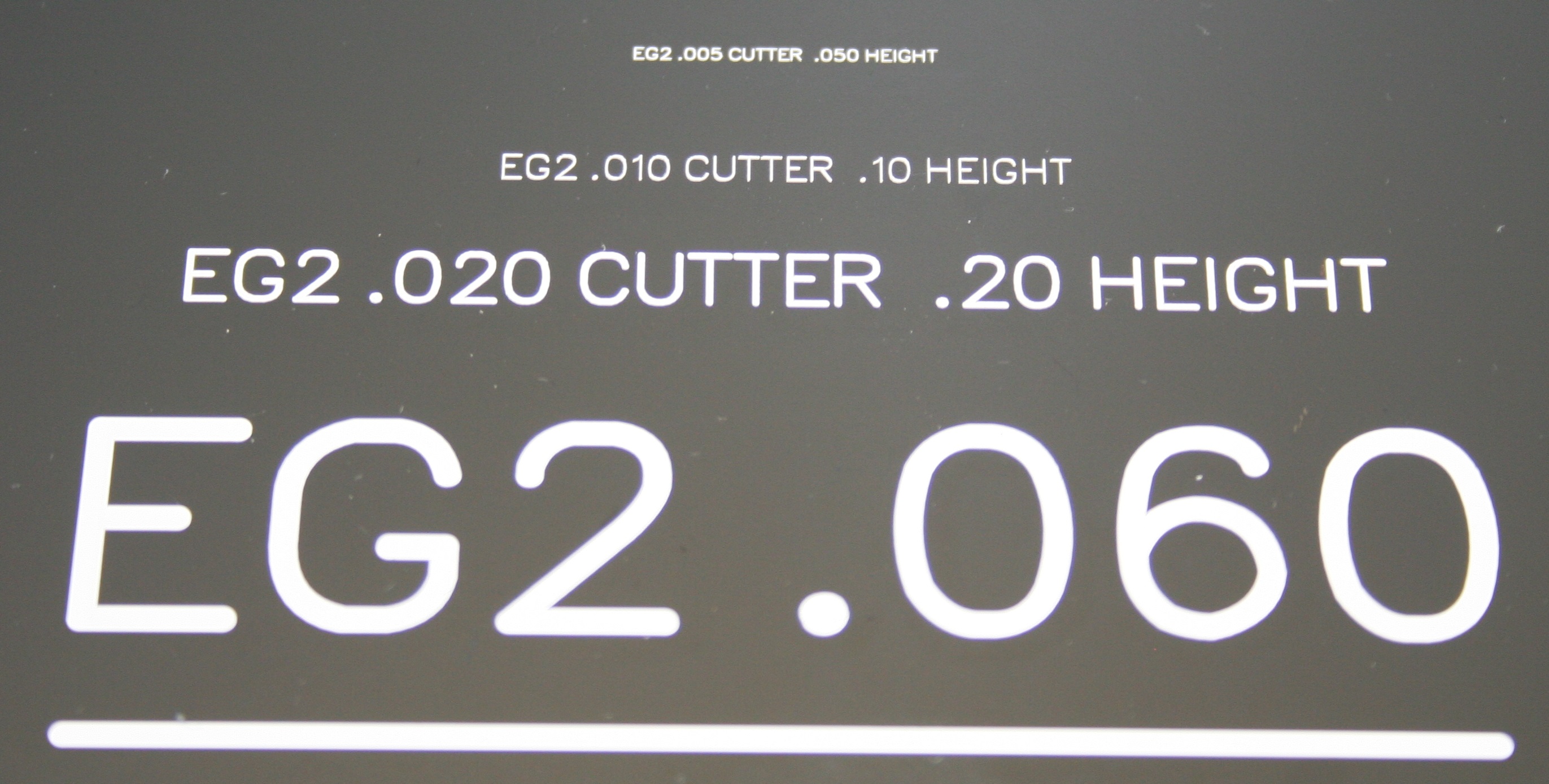

The test piece in the picture was engraved with the EG2 using 4 different cutters, from .005 tip widths and .050 text height to .060 tip width and .600 text height. In each case it was easy to cut only through the top coat and not touch the underlying metal. The cutters were zeroed on a hard surface and a test cut made. In this case the micrometer adjustment was set for -.001. Stated another way the cutter extended through the nose .001″.

The plate was painted with a .002 thick base of white SEM brand rattle can paint and a top coat of .001″ trim black. This was measured with a digital caliper. The EG2 can also cut the deeper cuts required in plastic engraving products.

The cut is made with the Panel Pro z zero on the material surface and the cut depth about -.03. This positions the Z axis but does not affect the depth that the engraving cutter penetrates the material. The engraving spindle is spring loaded and floats on the surface with the nose making contact with the surface. The actual cutter penetration is maintained with the micrometer nose adjustment of the EG2.

The EG2 includes the engraver assembly, one .010 tip width cutter, one 7/16 inch diameter steel nose, and 2, 1/4″ diameter Delrin nose pieces.