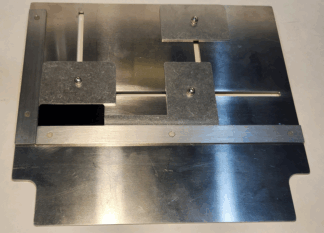

Description

When engraving instrument panels, the common practice is to first paint the panel with the color that you want the engraving to be, then paint the surface color.

The engraver or laser will then remove the top coat to reveal the first coat.

The EG2 engraver can easily set cutting depth to remove a couple thousands of paint and is adjustable to 1/2 of a thousand of an inch.

However the success of this process is dependent on consistent paint thickness on both the base coat and the top coat.

If the top coat is thicker in some areas, it is possible to re-adjust the depth and re-cut that area. However if the base coat is not thick enough, the engraving tool may cut completely through the paint into the panel base metal.

The paint thickness gauge is a tool that measures paint thickness. You can measure paint thickness with a caliper if you measured the panel before painting, but that only is accessible near edges or openings in the panel. The paint thickness gauge can measure anywhere on the panel. It can display microns or mils (thousands of an inch)

Note the exact product may vary from the picture.